The initial trial of three stores were 64-door combinations of Ambient, Frozen and Chilled lockers. Our lockers are modular 16-door units that link together and appear as a single block of lockers.

There was a large body of work completed to meet Countdown’s customer orders. Working backwards from an average shop size and how many bags would be required, Elocker developed a solution that met the capacity requirement. The ratio of Frozen: Chilled: Ambient lockers was also considered. Given the split required, Elocker designed and manufactured a new product to meet Countdown’s requirements – a Combo unit with eight doors of Frozen and eight Chilled compartments.

This combination was a perfect solution for when we rolled out the 32-door versions for smaller stores.

The trial quickly revealed that there was no need for Ambient lockers. One of the refrigeration features allows us to adjust the range of temperatures, so the Ambient was converted promptly into Chilled lockers.

Paramount in all of our thinking, and work with Countdown, was the customer experience. We addressed questions like the average shopping mix, what does the customer need from the locker pick-up experience, how far does the customer have to walk between multiple locker orders, and how quick and easy the pick-up experience is. One of the keys to answering these questions was the Terminals and User Experience generated by them.

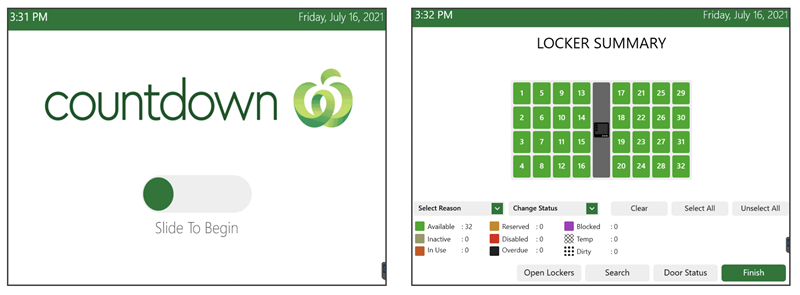

For the 64-door setups, we designed a two-terminal solution. The system is set, so the doors used for any order are as close to each other as possible. This algorithm saves customers from having to go from one end of the setup to the other. The screen also has an image (see below) of where the customer’s order resides. The doors also have LED lights to direct customers; plus, they pop open when the customer wants to access their order.

Elocker also added safeguards for Countdown’s customers. Accessing lockers multiple times if they closed, adding a buffer ‘finished’ time if a customer forgot to access a locker or left some goods in one and a multitude of small user experience touches ensures the customer has a safe, quick pick-up experience.

Integrating Elocker’s software, developed and improved with 12-years of international learnings, with Countdown’s e-commerce system was one of our first tasks. Our support team of developers worked closely with the Countdown team to ensure the systems were easy to manage, had the correct alerts for any variation in temperatures, and communicate correctly with customers.

Elocker also spent considerable time with Countdown establishing our ongoing support. As well as having our base support from what we know, we’ve also evolved our offer to meet Countdown’s specific needs. New Zealand also has some unique needs, so Elocker has adapted our support processes accordingly.

By having a well-established and proven software system driving the lockers, we delivered a successful integration.

Installing the lockers also takes a variety of skilled people. Elocker has assembled a team that complements each other’s skillsets, addresses any issues quickly and accurately, and always delivers gold-level work standards. As a result, Elocker has been able to provide several store installations in various locations and on a variety of surfaces. Organising a nationwide rollout with inevitable changes and disruptions caused by Covid19 also required careful planning.